Why sustainable beer brands are opting for more local ingredients?

Beer is the world’s most popular alcoholic drink. In fact, it’s behind only tea and water as the most commonly drunk beverage all around the globe¹. This ongoing popularity has created a $744 billion global beer industry² producing more than 2 billion hectoliters³ every year to sate our appetites.

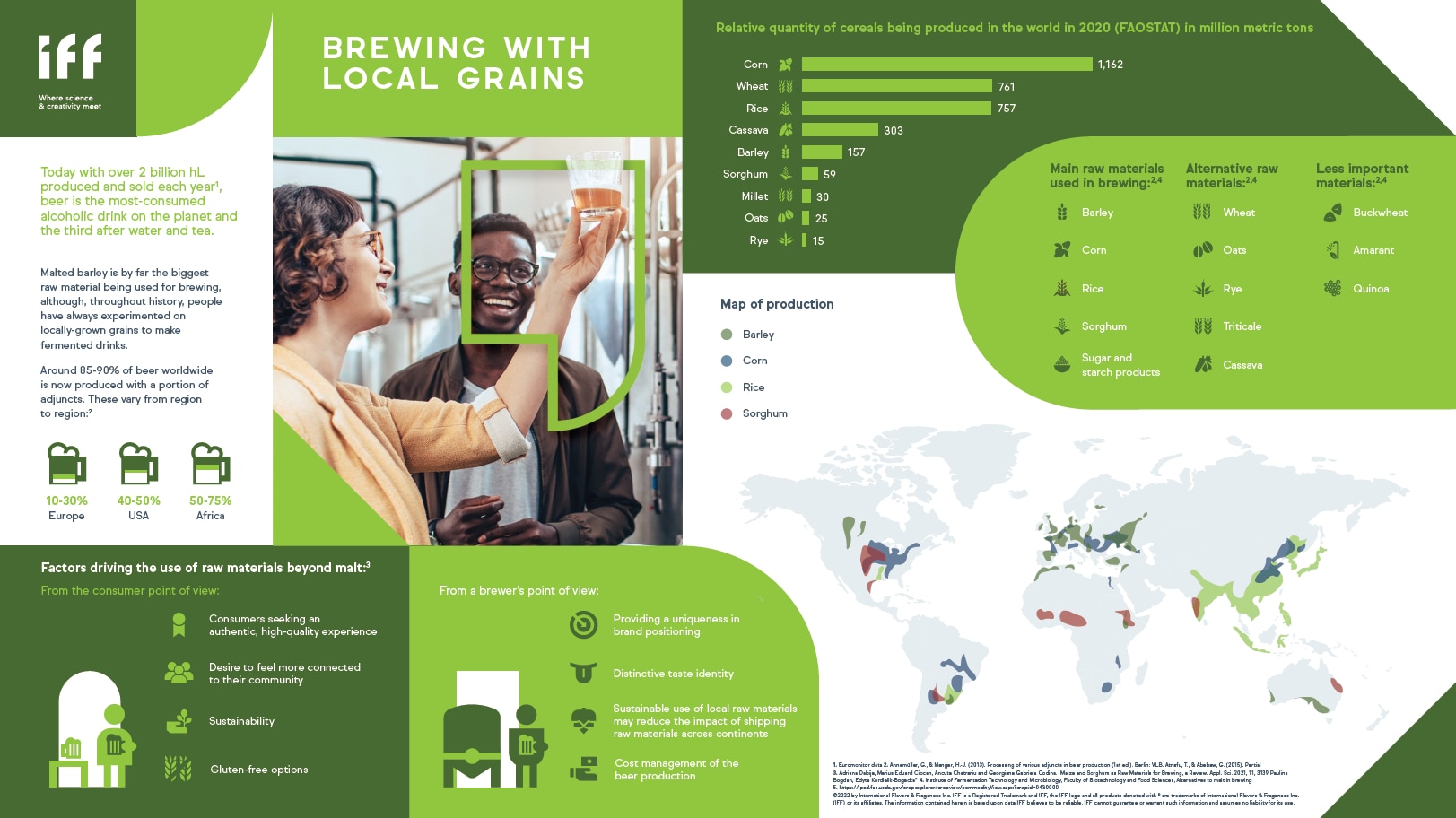

It is a sector that requires a lot of barley, which is by far the biggest raw material used in brewing⁴. In a process that goes back more than 5,000 years, brewers treat malted barley so that the dextrins contained in the grain are broken down to smaller sugars and are fermented into alcohol.

However, beer makers have always experimented with other types of grains grown locally from oats and corn to cassava and sorghum. To broaden their reach, expand their range of beers or to simply find cost savings, for many years, brewers have been adding alternative raw materials as adjuncts to supplement the main mash. Today, it is estimated that around 85-90% of all beer is produced with a portion of adjuncts, with beer makers in some regions using more than others. For example, between 10-30% of brewers in Europe use adjuncts, while up to 75% of African brewers do the same.⁵

So, why are brewers continuing to look past malt for their raw materials? A number of factors are at play. First, consumers are increasingly looking for a more authentic experience from their favorite beer brands – not just a high-quality drink but one that makes them feel more connected to their local community. Knowing that locally sourced ingredients are being used in their beer can do that.

Using alternative raw materials in their recipes can also help beer brands carve out a unique market position. New grains can offer new flavors and gluten-free options to reach new customers. And, technically, they can provide additional sources of fermentable carbohydrates, to change beer color, or to adjust flavors.

For beer makers looking to enhance their sustainability performance and credentials, local raw material use can give a suitable boost, with reduced shipping impacts and improved overall process efficiency, including water and energy. These obviously may have a positive impact on cost savings too. Local government policies to reduce imports and support local farming are also supporting the trend for using local crops in brewing.

Making the shift to use alternative raw materials is not without its challenges. Securing a supply of different grains that are commonly used for other, competing needs, such as food, will be key, as will be achieving the target beer quality and taste profile. Finally, the last thing beer makers will want is for their process efficiency to be impacted because of the introduction of new components in the brew.

But as the trend for localism – supporting local economies, feeling connected to the local community, buying into brands that care about the places they operate – escalates, finding alternatives to traditional beer making processes presents a huge opportunity for beer companies to grow and thrive in a crowded market.

¹. Dabija A., Ciocan M.E., Chetrariu A. & Codina G.G. Maize and Sorghum as Raw Materials for Brewing, a Review. Appl. Sci. 2021, 11,3139.

². Vantage Market Research, https://www.globenewswire.com/news-release/2022/09/22/2520839/0/en/Global-Beer-Market-Size-to-Worth-US-915-4-Bn-by-2028-at-a-CAGR-of-3-5-Rising-Social-Drinker-to-Drive-the-Market-Growth-Vantage-Market-Research.html

³. Euromonitor

⁴. American Scientist, https://www.americanscientist.org/article/why-brewers-choose-barley

⁵. Annemüller, G., & Manger, H.-J. (2013). Processing of various adjuncts in beer production (1st ed.). Berlin: VLB. Atnafu, T., & Abebaw, G. (2015). Partial